We create the materials you need to make your products even more special. Anything from fine grain stabilized wood to rare ice age fossils. Let us know the project and we will find the right material!

Raffir is taking a new approach to material design. Everyday we strive to take something traditional and practical and turn it into an art form. And we have been doing so since 2003.

Usually our customers already make very appealing quality products, both as fine crafts and industrial high-end goods. So at first we have to ask ourselves: How can Raffir materials help our customers make even better products? Surely, they have to stand out from all the rest. They have to be more special, more beautiful, have a better story – simply be more appealing to the customers. All that while still meeting the requirements for strength, durability, machinability and safety.

This leads us to a whole variety of new materials. Every time we start a new project we want to create something original. To help us do that we even create entirely new manufacturing methods. Careful selection is another way of insuring a high quality. Therefore, we put a lot of effort into product development. Actually, for every product we put on the market there are about 10 more on our R&D shelves. And every time we launch a new product we set the bar a little bit higher. Thereby we ensure better and better products for our customers.

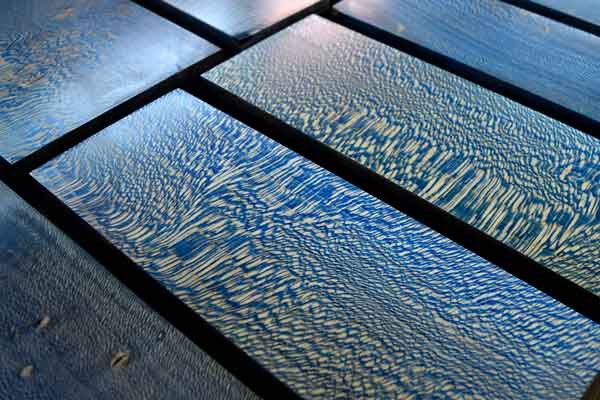

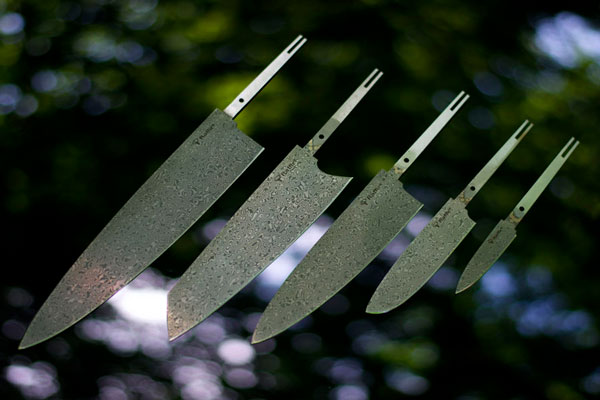

We offer products in three main categories: Raffir Wood, Raffir Fossils and Raffir Blades. We carefully select fine-grained wood and stabilize it into Raffir Wood. The stabilization process is our own unique high-pressure resin treatment. After this process the material is stronger, more durable and has deeper grain patterns. Our Raffir Fossils are real ice age mammoth fossils that we preserve with a similar process. We make these rare and special materials useful through the stabilization process. Finally, Raffir Blades is our own high grade knife blade series. The blade designs all draw inspiration from our Scandinavian heritage. They are based on the principle that form follows function. Therefore, each design is developed in close cooperation with experienced makers and users such as knife-makers, hunters and professional chefs. All of their inputs are then combined into the simplest and most elegant design possible. When it comes to manufacturing we use precision CNC-milling and premium steel types, such as VG10 and solid stainless damascus.

This is our quality brand of stabilized wood. Raffir Wood is naturally fine figured wood that is filled to the core with a durable resin. The process improves hardness, strength, water resistance and polishability, while giving it a smooth 3D depth.

These beautiful ancient wonders meets modern technology at Raffir. Raffir Fossils are genuine ice age mammoth fossils that are also stabilized to the core with a durable resin. The result is a beautiful piece of history with good strength and integrity.

Our own Scandinavian style design series of chef knife blades, hunting knife blades and folder kits. Created alongside experienced knife makers, hunters and professional chefs, so that we can offer you the best blades to fit the best materials.

Most of our customers use our materials for fine knife handles. And our materials and blades definitely work well together. Meanwhile, this is far from the only application. Our customers also use them for accessories, jewelry, inlays, musical instruments, pool cues and fishing rods etc. Actually they work well in most small and medium-sized quality products. Use them where you want that extra edge to your products.

Hope you made it through the text. Then let us move on to the fun part! Please browse through our materials below or by the top menu. Enjoy!

You can also follow our Facebook and Instagram account for updates!

Our Raffir Wood is a high quality brand of stabilized wood. It is also the core product of our company. We have more than 15 years of experience developing and producing stabilized wood. It is a continuous cycle. Hence, we always strive to make it better, stronger and more beautiful. We create it from fine wood that we fill to the core with a specially developed resin. The final material has the fine grain patterns of the untreated wood. Meanwhile, it obtains the mechanical benefits from the strong resin. In other words, it unites the best parts from both worlds.

Raffir Fossils are real mammoth fossils from the last ice age (10,000-40,000 BP). Needless to say, this rare material is in itself very special. For that reason it also makes unique products such as knife wood materials even more special. Occasionally, tusks, molars and bones are found from these iconic mammoths. Each type is very different. Therefore we have developed a unique preservation treatment for each of them. All of the treatments stabilize the fossils with vacuum, high pressure and strong resins. The resins we use differ depending on the materials and if it will be used for a knife handle or musical instrument for example. Nonetheless, they all result in stronger knife handle materials that is useful for a wide array of luxury products. We recommend Raffir Fossils material for jewelry, a knife wood grib, inlays, accessories and other precious objects. Feel free to see our inspiration catalog for new ideas.

When you want a really nice knife blade with your really nice knife materials… Raffir Blades is our own high grade knife blade series. The blade designs all draw inspiration from our Scandinavian heritage. They are based on the principle that form follows function. Therefore, each design is developed in close cooperation with experienced makers and users such as knife-makers, hunters and professional chefs. All of their inputs are then combined into the simplest and most elegant design possible. When it comes to manufacturing we use precision CNC-milling and premium steel, such as solid stainless damascus and other high alloy steel types.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.